The industry of garment manufacturing is experiencing a transition to the digital space, and Industrial IoT (Internet of Things) is at the core of this process. Such transition is being actively promoted at such events as software & automation expo, when garment businesses may look at the ways how technology may improve their efficiency, quality and competitiveness of the production.

Real-Time Monitoring for Better Control

IoT enables the garment manufacturing industries to have real time monitoring of their production processes. The equipment is linked with machine, sensors and system to give live updates of equipments, cutting fabric, stitching, etc. Such a visibility assists in revealing problems at an early stage, minimizing downtime, and promoting the flow of work. The software & automation expo demonstrates the role of real-time monitoring in the enhancement of the speed and precision on the floor in garment factories.

Smarter Inventory Management

Raw material such as fabric, threads, accessories and trims can be difficult to manage. Through Industrial IoT, stocks levels and consumption rates can be monitored automatically. The companies are notified when they are about to run out of supplies keeping them free of delays. In inventory management, some of the vendors have exhibits at the software & automation expo that minimize wastage and enhance the planning of orders.

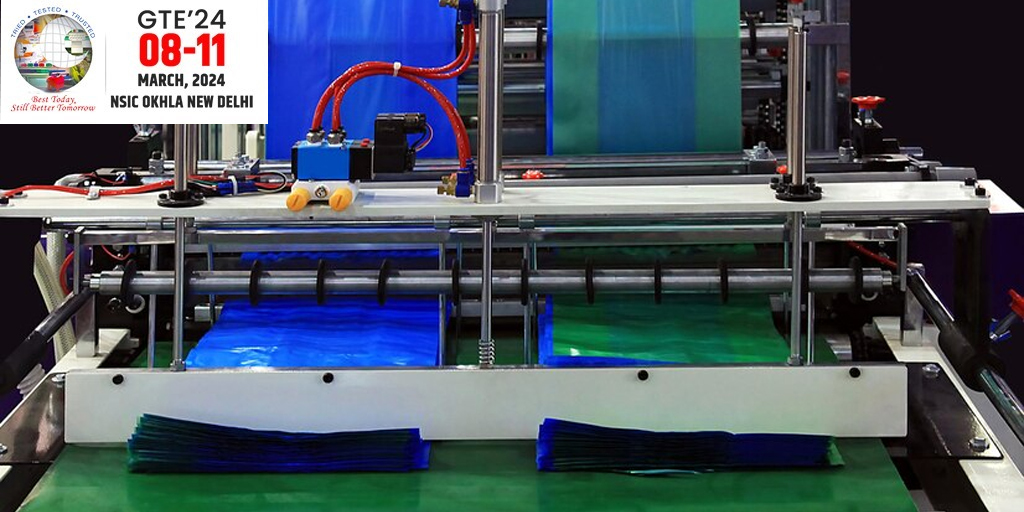

Improved Product Quality through Automation

Manual checks are likely to miss checking garments defects. Misaligned stitches or wrong size will be detected at an early stage when one operates IoT-driven quality control systems. The systems offer feedback throughout the cycle of productions. Live demos available on the software & automation expo reveal how the automated quality inspection is acquiring a natural feature of the contemporary garment production process.

Ensuring Worker Safety and Comfort

A healthy work environment is essential for any manufacturing unit. Industrial IoT systems can monitor air quality, temperature, and humidity levels inside the factory. These tools help ensure compliance with safety standards and promote worker well-being. Many stalls at the software & automation expo focus on worker safety tech, offering solutions that combine productivity with employee care.

Streamlined Production Processes

When different departments in a garment unit are digitally connected, workflows become more efficient. Once a task like fabric cutting is completed, the next team is instantly notified, reducing idle time. The Software & Automation Expo often features systems that enable such automated coordination, showing how garment manufacturers can save time and increase output without expanding their workforce.

Supporting Sustainability Goals

Industrial IoT also plays a role in making garment manufacturing more sustainable. It helps track energy and water usage and points out areas of excess. This allows factories to take corrective steps and reduce their environmental impact. Sustainability-focused solutions at the Software & Automation Expo demonstrate how connected systems can support greener production practices.

A Platform for Innovation and Adoption

The software & automation expo has become an essential platform for garment manufacturers aiming to keep pace with innovation. It brings together technology providers, automation experts, and factory owners to explore practical applications of Industrial IoT. Whether it is optimizing inventory, improving quality, or enhancing workplace safety, the expo provides real-world insights into the benefits of digital adoption.

Conclusion

Industrial IoT is shaping the future of garment manufacturing by making operations more efficient, safe, and responsive. Events like the software & automation expo serve as a gateway for manufacturers to learn, adopt, and implement these technologies in their own facilities. As the industry evolves, the role of Industrial IoT will only become more vital in driving productivity and sustainability in garment production.