Textile and apparel segment is also changing with new fashion trends, demands of the customers and new idea in the field of fabrics. One of the largest tasks in this transformation is propelled by innovation in knitting machinery & equipments, which now have grown much specialized to the point of being adapted to very specific applications such as sportswear, outerwear, and intimate apparel. Through these machines, manufacturers can design real fashion without giving up on functionality and comfortability of a garment.

As many people rush to use performance fabrics, and as different uses of these materials apply, it is important to understand how to use knitting machines to match a particular mission. Current machines are based on specific needs of varieties of garment to enhance its quality, consistency, and production efficiency.

Knitting Machinery for Sportswear

Sportswear requires high comfortability, flexi-ability, breathability as well as durability. To achieve these requirements the knitting machines and equipments used in sportswear production are fitted to make materials that have stretch and moisture and strength giving abilities.

As an example, circular knitting machine is widely known to knit seamless garments or high stretch jerseys such as those found in running, cycling, or yoga activities. Mesh structures and elastic fabrics suitable to sports t-shirts, leggings and compressions can be created in a double jersey machine and a warp knitting machine. With these machines manufacturers have the ease of tensioning and dense appropriation to suit the demands of the various sports of performance.

Knitting Machinery for Outerwear

It includes outerwear, e.g. sweaters, cardigans, jackets and lighter pullovers, which may usually need more machines that are able to work with a thicker yarn, and move into intricate designs. It is especially helpful in the use of flat knitting machines, which can be used to design in a more varied way and they can additionally work with heavier materials.

New knitting gear & equipments of outerwear have the means of generating a texturized and structurized codification and yet offer warmth, insistence, and design. Knit-and-wear technology is also facilitated in these machines which bring down the number of steps required to complete garment production, saving time, as well as material. To give the trendy and practical outerwear range, the correct equipment spells the difference sexily and comfortably.

Knitting Machinery for Intimate Apparel

Intimate apparel, such as lingerie, undergarments, and shapewear—calls for soft, stretchable, and form-fitting fabrics. This makes it essential to use knitting machinery & equipments that specialize in producing fine and smooth fabrics with elasticity.

Machines like seamless circular knitting machines and warp knitting machines are popular for these applications. They can create garments with fewer seams, better fit, and enhanced comfort. Knitted fabrics for intimate apparel need to be breathable, lightweight, and supportive—qualities that today’s advanced knitting machines can consistently deliver.

Why GTE is the Ideal Platform to Explore These Technologies

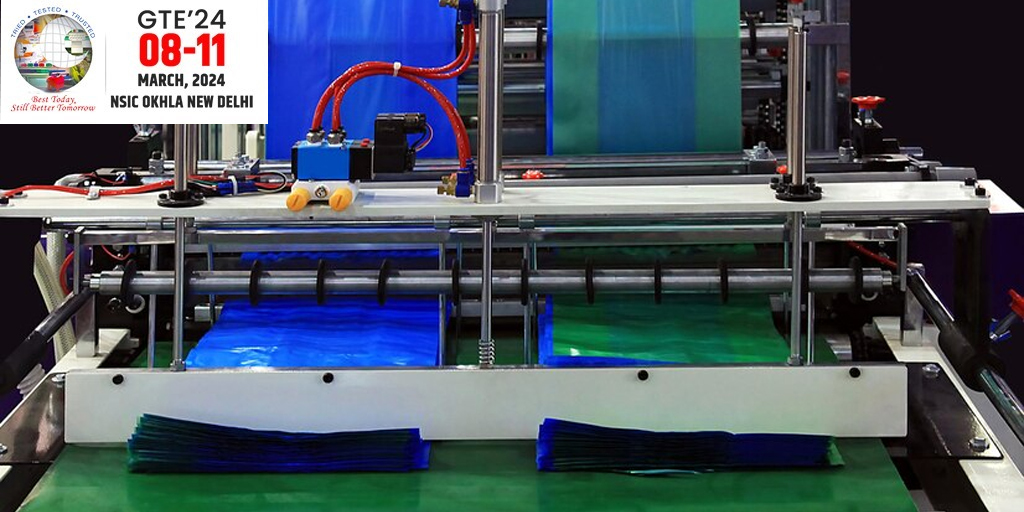

For businesses and professionals looking to explore the latest in knitting machinery & equipments, the Garment Technology Expo (GTE) serves as the ideal platform. GTE brings together leading machinery manufacturers, textile innovators, and industry professionals under one roof.

Whether you’re looking for machines to support large-scale sportswear production or searching for the latest seamless knitting equipment for lingerie, GTE showcases a wide range of machinery suited to every segment. Visitors can see live demonstrations, interact with machine makers, and understand how new technologies can fit into their operations.

The expo also offers insights into market trends, sustainable production practices, and innovations that help reduce energy consumption or material waste. For companies aiming to upgrade their manufacturing capabilities, GTE provides the knowledge and connections needed to make informed decisions.

Conclusion

The world of fashion and functional wear continues to diversify, and so do the machines that support their creation. From stretchable sportswear to cozy outerwear and delicate intimate apparel, specialized knitting machinery & equipment have become essential to meet consumer demands and maintain production efficiency.

As the industry evolves, staying updated with the latest technologies is key. Platforms like the Garment Technology Expo (GTE) offer the perfect opportunity to discover advanced knitting machines and learn how they can be applied across different apparel categories. Whether you’re a small manufacturer or a large textile house, GTE is your go-to destination for the latest in knitting machinery.