The finishing paints business is literally changing faster than lightning as there is pressure to be more precise, efficient, and greener. With the coming Finishing Equipment Exhibition of this year, the audience is likely to get enamored by the display of the latest breakthroughs and novelties that alter the notions of surface finishing and finalization. From eco-friendly coating and cutting-edge robotics to intelligent automation and future nanotechnology, the show is sure to feature some of the newest developments that are not only revolutionizing the finishing business but also setting new benchmarks for finishing. You want to be a manufacturer, an industry insider, or even a designer, this EAF event provides you with a front row seat to the future of finishing technologies. Now we will discuss the latest trends of the finishing equipment exhibition.

Finishing Equipment Exhibition: What are the Latest Trends?

Automation & Robotics Take Center Stage

Automation and robotics are the new key players in the advance finishing due to high levels of precision and speed and reliability without any parallels. With the combination of high-tech robot systems and intelligent automation, manufacturers reach constant results with a minimum of human mistakes and manual work. The technologies provide an efficient process in production, improve safety at workplaces and fulfill an increasing need of perfection in terms of surface finishes. With the increased automation, organizations are able to produce more goods with less cost of production hence resulting in high quality standards. This trend indicates a fundamental change in the theme of finishing by smart, efficient production which is a redefinition process to fields of surface preparation and perfection. Automation & robotics is one of main trends that is highly expected in finishing equipment exhibition.

Sustainability at the Forefront

The finishing industry pays a lot of attention to sustainability, and there has appeared a new solution allowing performing the necessary functions without being harmful to the environment. Inventions are focusing on energy efficiency of processes, safer materials and methods that reduce wastes and utilization of resources. Environmentally-friendly coatings, more sophisticated recycling technology are just a few of the ways in which manufacturers are able to address any increased industry regulations and consumer demand of greener products. A focus on sustainability helps the companies to appear as the responsible leaders in their business and help the world as well to decrease carbon footprints on the planet. This firm dedication to the environmentally friendly standards will turn finishing into the future cleaner and more responsible.

AI & IoT: Smart, Connected Finishing

The advent of IoT and artificial intelligence is transforming finishing equipment into smart, networked machines. With these technologies, real-time monitoring, data-based adjustments, and advanced process control are enabled, which result in higher productivity and more reliable outcomes. Using AI, manufacturers can enhance overall product quality, reduce downtime, and maximize operations. In addition, IoT connectivity enhances predictive maintenance and traceability so possible issues can be actively resolved ahead of time before they create disruptions. A significant development in finishing technology, this move towards smart, flexible systems allows businesses to stay competitive while consistently delivering outstanding finishes with minimal support.

Nanotech & Advanced Surface Functionalities

You can also expect nanotech & advanced surface functionalities in finishing equipment exhibition. Surface finishing is being revolutionized by nanotechnology, which offers improved performance and sophisticated functions. At the microscopic level, new coatings can increase longevity, offer superior protection from environmental elements, and boost visual appeal. These high-performance coatings provide distinctive qualities including increased smoothness, enhanced resistance, and specialized surface effects, which assist prolong the life of products and add value. Nanotechnology integration into finishing processes is becoming more and more crucial as the need for creative and higher-quality solutions increases. With this trend, finishing is being approached with an eye toward the future, enabling producers to provide better outcomes that satisfy changing performance requirements and market expectations.

Conclusion

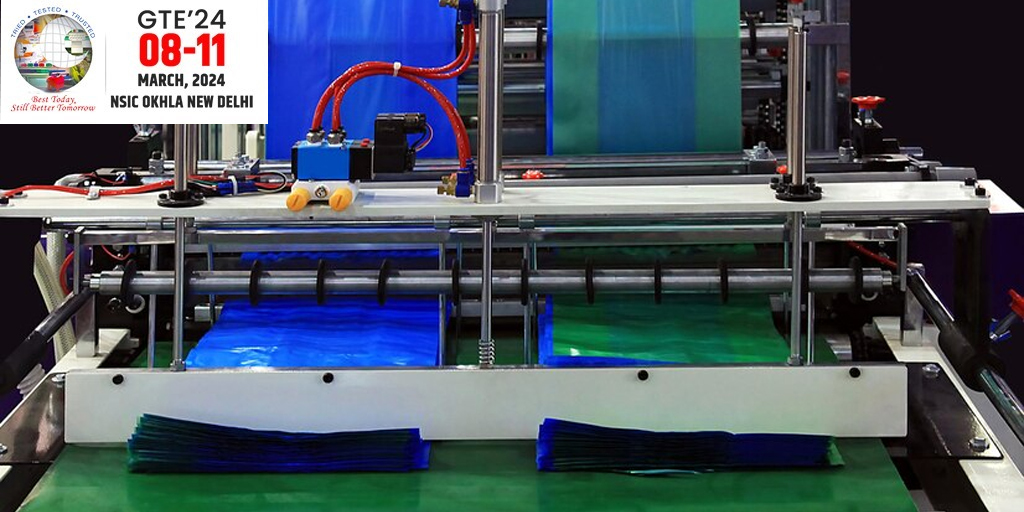

The finishing equipment exhibition is more than just a showcase, it’s a glimpse into the future of precision, sustainability, and smart innovation. From advanced automation and robotics to eco-friendly solutions and cutting-edge nanotechnology, this event highlights the trends shaping the next era of surface finishing. GTE brings together top-quality finishing equipment that integrates advanced automation, smart AI connectivity, sustainable practices, and next-generation surface technologies.