Denim has always been a universal and classic fabric type all around the world, worn by all age groups and by all cultures. Rough jeans, trendy jackets, and skirts made of denim have entered the mainstream of the fashion industry. Increased consumer demand and demand of quicker and accurate production are driving the manufacturers to seek greater productivity and consistency through advanced machines in production. The Denim Garment Making Machinery Expo is the most ideal arena to investigate these advances in the industry.

The expo will congregate the newest advancement in the manufacture of denim garments to enable manufacturers to keep up to date with the tools that are efficient, faster and smarter than before. Through high-speed sewing machine to automatic pattern-cutting system the event features the available machinery that is bound to change the production of the denim garments.

High-Speed Sewing Machines

The production of denims today depends very much on the availability of sewing machines that can work through the thick cloths at great speed and with lot of proficiency. The machines would be used to make durable seams, would control stitch quality even at the high pace, and keep the operator energy in check. several machines are being equipped with programmable settings that have many types of stitches and other requirements of a garment.

Manufactures get the chance to observe in action the demonstration of these sewing machines at the Denim Garment Making Machinery Expo. When it comes to marking pockets, jean hemming or waistband sewing, these are designed to meet two of the most important requirements in denim manufacturing, which are time and toughness.

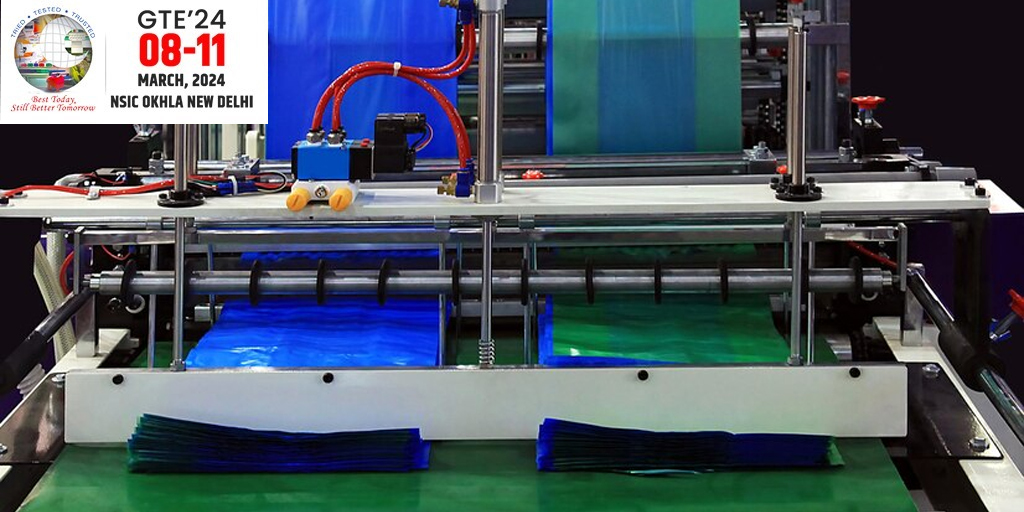

Automatic Pattern-Cutting Systems

The process of cutting fabric is one of the most significant aspects in the process of denim garment making. Manual cutting procedures have been substituted with automatic systems of pattern-cutting with the improvement in cutting technology. Such systems are capable of slicing through several layers of denim fabrics precisely and rapidly, through digitized patters which can be edited on the go.

Denim Garment Making Machinery Expo offers various automated cutting systems that save on the wastage of fabrics and maximize work. Such systems guarantee order within each piece of garment, error minimization, and improvement in production schedules. Some even come with built-in fabric recognition features, which help in adjusting the cutting style based on fabric thickness and type.

Laser Finishing and Washing Equipment

Another highlight of modern denim production is the use of laser technology for creating stylish finishes. Laser machines are used to create whiskers, fades, and other design effects without using water or harsh chemicals. This not only offers precision but also makes the process more sustainable.

At the Denim Garment Making Machinery Expo, visitors can explore laser finishing machines that offer unique capabilities for both large and small production units. With growing awareness about sustainable practices, such technologies are becoming a must-have for forward-thinking manufacturers.

Seamless Integration of Technology

Today’s denim garment making machinery doesn’t operate in isolation. Many systems are now integrated with software that allows monitoring of production, detection of errors, and data-driven decision-making. This integration helps manufacturers keep track of production efficiency, downtime, and quality control.

The Denim Garment Making Machinery Expo showcases solutions that connect cutting, sewing, and finishing systems with digital dashboards. These smart setups are ideal for manufacturers who want to modernize their operations and keep up with global standards.

Why the Denim Garment Making Machinery Expo Matters

The Denim Garment Making Machinery Expo is more than just a showcase of machines—it’s a learning platform. Industry professionals, technology experts, and suppliers gather to exchange ideas and discuss the future of denim garment production. Whether you are a startup looking to invest in your first set of machines or a large manufacturer aiming to upgrade, this expo offers insights and access to the best the industry has to offer.

Conclusion

The denim industry continues to grow and evolve, driven by consumer demand for stylish and durable clothing. To meet this demand, manufacturers need reliable and advanced machinery. From high-speed sewing machines to intelligent cutting systems, the tools of modern denim garment making are smarter and more capable than ever before.

The Denim Garment Making Machinery Expo offers a window into these innovations, helping businesses adopt the right technology for their needs. It’s the place where ideas meet execution, and where the future of denim production begins.